- TRANG CHỦ

- GIỚI THIỆU

- SẢN PHẨM

- Nguyên liệu ngành nhựa

- Hóa chất ngành Giấy

- Trợ bảo lưu và thoát nước

- Chất tăng bền ướt

- Chất phủ lô

- Hóa chất giặt chăn lưới

- Chất diệt khuẩn

- Tăng trắng huỳnh quang

- Lơ tím, xanh

- Trợ chống thấm bề mặt

- Phẩm màu cho giấy bao bì

- Phẩm màu cho giấy bìa màu

- Hóa chất cho giấy tráng phủ

- Chất phá bọt

- Chất tăng bền khô

- Hóa chất xử lý nước thải

- Chất phân tán Tissue

- Chất khử mực

- Hóa chất ngành sơn

- Nguyên liệu xi măng

- Hóa chất công nghiệp

- Hóa chất ngành dệt nhuộm

- TIN TỨC

- KỸ THUẬT

- KHÁCH HÀNG

- TUYỂN DỤNG

- LIÊN HỆ

DANH MỤC SẢN PHẨM

TÀI LIỆU KỸ THUẬT

- tdsp640j.pdf

- propertyanalysiswt45ancalpha.pdf

- tdspalmac1600alpha.pdf

- tdspalmac1500alpha.pdf

- stearicacid1838alpha.pdf

- coaofstearicacidr401860alpha.pdf

- deepwhiteabpxpowderalpha.pdf

- kymenẹ57htangbenuotvn.pdf

- prosofttq28881.pdf

- tdskymene705.pdf

- kymenẹ57htds.pdf

- hyt80tdsenalpha.pdf

- snowhite80tdsvietnam.pdf

- pmmacm207.pdf

- pc110uiso.pdf

- opticalbrighteningagent2plc.docx

- opticalbrighteningagent4plcvn.pdf

- melaminetdsalpha.pdf

- coazncl2alpha.jpg

- tdszncl2alpha.pdf

- pc1220ueng.pdf

- pc1100u.pdf

- pc1070ueng.pdf

- absag15átds.pdf

- ppk8009tdsen.pdf

- absterlurangp35.pdf

- absterlurangp22.pdf

- bakelit161jcoaalpha.pdf

- bakelit151jcoaalpha.pdf

- bakelit141jcoaalpha.pdf

- bakelit141coaalpha.pdf

- makrolonet3117isoen.pdf

- makrolonet3113isoen.pdf

- makrolonal2647isoen.pdf

- makrolon2807isoen.pdf

- makrolon2407isoen.pdf

- alphavncompanyprofile.pdf

- HẠT NHỰA NGUYÊN SINH

- Hạt nhựa PC

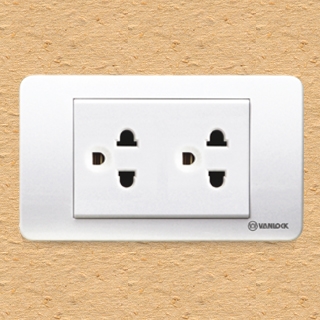

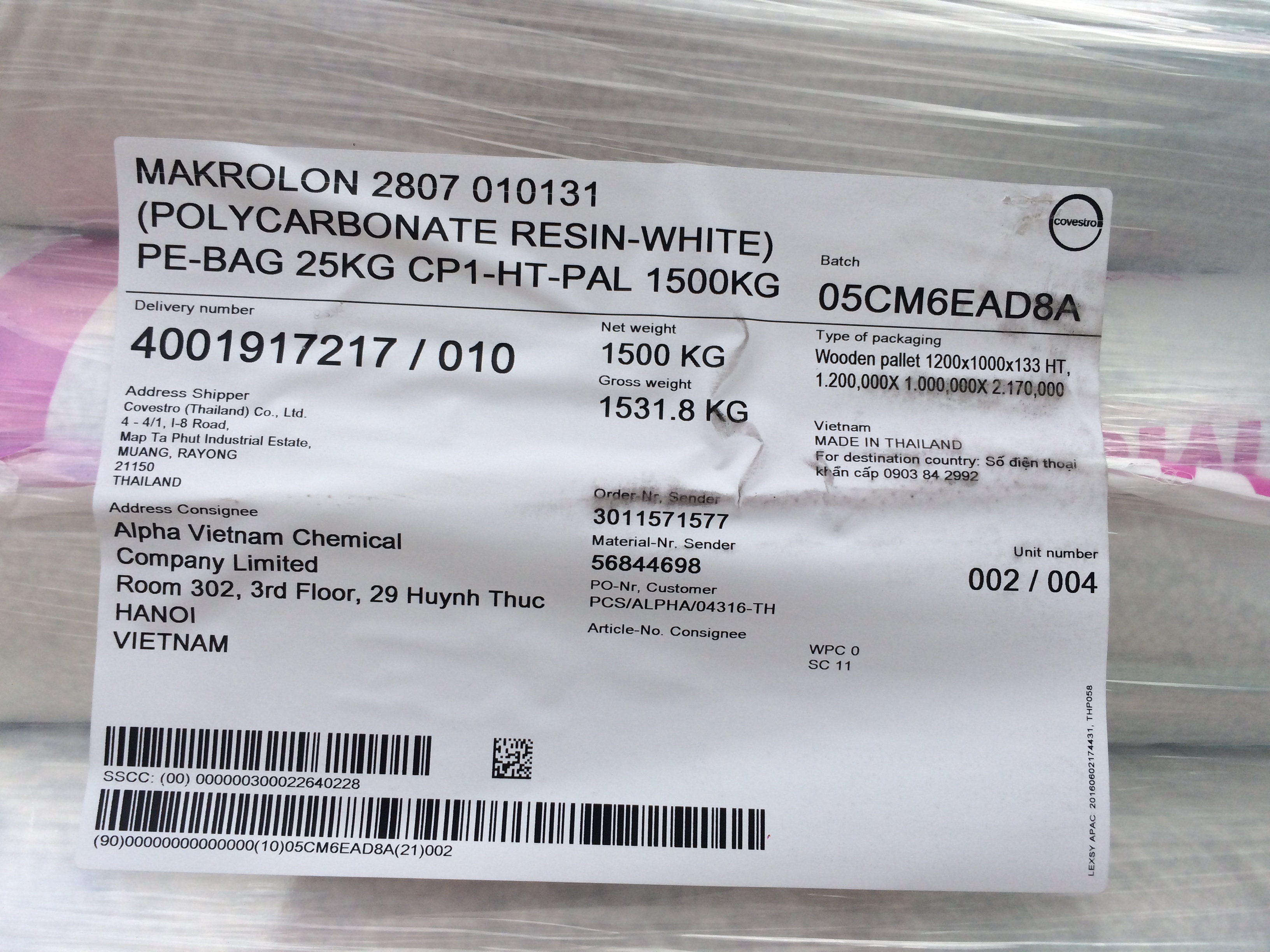

Hạt nhựa PC 2407, 2807 010131 (trắng điện)

| Tên sản phẩm: | Hạt nhựa PC 2407, 2807 010131 (trắng điện) |

|---|---|

| Mã sản phẩm | Makrolon 2407, 2807 01013 |

| Nhóm sản phẩm: | Hạt nhựa PC |

| Lượt xem | 12597 |

| Mua hàng | |

Hạt nhựa PC Makrolon 2407, 2807 010131, trắng điện (Bayer)

Polycarbonate Makrolon trắng điện, mã 2407; 2807

Mã màu: 010131 (trắng điện)

Description

Makrolon 2405, 2407, and 2458 polycarbonate resins are

linear, low-viscosity, high-performance thermoplastics

produced in pellet form for processing primarily by

injection molding. A unique technology enables these

polycarbonates to maintain mechanical properties similar

to lower-melt-flow grades of standard polycarbonate,

while offering improved flowability for increased

design flexibility. Makrolon 2407 resin is UV-stabilized.

All three resins contain an internal mold release additive.

They are available in natural clear, clear tints, and

transparent, translucent, and opaque colors, and with

special visual effects.

By broadening the processing window, Makrolon

2405, 2407, and 2458 resins are designed to permit

faster cycling and higher productivity. Based upon tests

conducted at Bayer laboratories, a processing comparison

of Makrolon 2405 polycarbonate resin with production

runs of standard polycarbonate has demonstrated

increases in production rates in excess of 15%. Actual

test results may vary, depending on the application

and processing conditions. In addition, the increased

productivity reduces energy consumption on a unit

part basis.

These benefits are the result of low melt viscosity and

ease of part ejection. The low viscosity is of particular

interest in applications where thin walls exist or the

flow length-to-wall thickness is high. Ease of processing

at lower temperatures translates to faster cycles, as parts

may be produced at lower mold-set-point temperatures

and ejected after shorter cooling times. Although

applicable to existing tools, new tool design can take

advantage of the low melt viscosity of these grades.

Thinner runners and distribution systems can be

employed to minimize regrind and reduce cycle time.

Wall sections in the part can be reduced to conserve

materials and contribute faster cycling.

Although small parts offer some of the more attractive

benefits of increased productivity, these grades are also

candidates for applications involving large injection

molded parts. In both large and small part molding,

the same processing allowances exist. Lower melt

temperatures and easy release permit demolding with

less time necessary for stabilizing the part.

Makrolon 2458 resin complies with FDA food-contact

regulations 21 CFR 177.1580 (Polycarbonate Resins)

and may be used in contact with all food types. Most

colors may be used for all thermal food-contact

applications. However, some colors are limited by

Conditions of Use B, 21 CFR 175.300 and 176.170

and may not be used when the food is sterilized in the

food-contact article under autoclaving conditions.

Please contact your Bayer Corporation representative

with complete details when food contact is involved.

Makrolon 2458 resin, in natural 000000 and clear tints

550042 and 550115, is also listed under NSF standard

51 for use in food equipment. Please consult your Bayer

Corporation representative for more information about

food equipment applications.

Applications

Makrolon 2405, 2407, and 2458 resins are utilized over

a wide range of applications in a variety of market areas.

Typical applications include automotive light pipes,

clear windows for business machines and instruments,

and numerous consumer applications where multicavity

tooling is used. As with any product, use of Makrolon

2405, 2407, or 2458 resin in a given application must

be tested (including but not limited to field testing) in

advance by the user to determine suitability.

Medical Applications

Makrolon 2458 resin is used in a variety of medical

devices.

Biocompatability:Certain color formulations of

Makrolon 2458 polycarbonate resin (such as clear tint

550115) meet the requirements of the FDA-modified

ISO 10993, Part 1 “Biological Evaluation of Medical

Devices” tests with human tissue contact time of 30

days or less.Only products that meet these require-ments may be considered candidates for applications

requiring biocompatibility.

Regrind must not be used in medical applications

requiring biocompatibility.

Manufacturer’s Responsibility: It is the responsibility

of the medical device, biological product or pharma-ceutical manufacturer (“Manufacturer”) to determine

the suitability of all component parts and raw materials,

including Makrolon 2458 resin, used in its final product

in order to ensure safety and compliance with FDA

requirements. This determination must include, as

applicable, testing for suitability as an implant device

and suitability as to contact with and/or storage of

human tissue and liquids including, without limitation,

medication, blood or other bodily fluids. Under no

circumstances may Makrolon 2458 resin be used in

any cosmetic, reconstructive or reproductive implant

applications. Nor may Makrolon 2458 resin be used in

any other bodily implant applications or any applications

involving contact with or storage of human tissue, blood,

or other bodily fluids for greater than 30 days, based

on FDA-modified ISO 10993, Part 1 “Biological

Evaluation of Medical Devices” tests.

The suitability of a Bayer product in a given end-use

environment is dependent upon various conditions

including, without limitation, chemical compatibility,

temperature, part design, sterilization method, residual

stresses, and external loads. It is the responsibility of

the Manufacturer to evaluate its final product under

actual end-use requirements and to adequately advise

and warn purchasers and users thereof.

Single-use medical devices made from a Bayer product

are not suitable for multiple uses. If the medical device

is designed for multiple uses, it is the responsibility of

the Manufacturer to determine the appropriate number

of permissible uses by evaluating the device under actual

sterilization and end-use conditions and to adequately

advise and warn purchasers and users thereof.

Sterilization: Parts molded from Makrolon 2458 resin

are sterilizable using radiation, ethylene oxide, or steam

autoclaving. When sterilizing with steam, germicides

and detergents must be rinsed thoroughly from polycar-bonate parts prior to autoclaving. Failure to thoroughly

remove germicides and detergents from the part prior

to autoclaving may cause accelerated degradation of

the polycarbonate.

Steam sterilization temperatures for parts made of

Makrolon polycarbonate must not exceed 250º F

(121ºC) to avoid part deformation. Please note that

permanent immersion of polycarbonate parts in water

above 140ºF (60ºC) or in steam causes loss of material

properties and must be avoided. Furthermore, condensed

steam should not be allowed to accumulate, as this

may cause damage to parts. Polycarbonate parts should

also be protected from damage by substances such as

alkaline corrosion inhibitors, which are frequently

added to boiler feed water.

The sterilization method and the number of sterilization

cycles a medical device made from Makrolon 2458

resin can withstand will vary depending upon type/

grade of product, part design, processing parameters,

sterilization temperature, and chemical environment.

Therefore, the Manufacturer must evaluate each device

to determine the sterilization method and the number

of permissible sterilization cycles appropriate for

actual end-use requirements and must adequately

advise and warn purchasers and users thereof.

Drying

All polycarbonate resins are hygroscopic and must

be thoroughly dried prior to processing. A desiccant

dehumidifying hopper dryer is recommended. To

achieve a moisture content of less than 0.02%, hopper

inlet air temperature should be 250°F (121°C) and

inlet air dew point should be -20°F (-29°C) or lower.

The hopper capacity should be sufficient to provide

a minimum residence time of 4 hours. Additional

information on drying procedures is available in the

Bayer brochure General Drying Guide.

Processing

Makrolon resins may be easily processed on

commercially available molding equipment suitable for

injection molding of polycarbonate. Barrel temperatures

may be reduced by up to 45°F (25°C) below normal

processing conditions for standard polycarbonate due

to ease of cavity fill. Lower viscosity also means that

lower primary and secondary injection pressures may

be used and that molded-in stresses should be lower.

A lower melt temperature permits the use of shorter

hold and cure times. The shorter molding cycle is

complemented by ease of part ejection at high part

temperatures.

Typical processing parameters are noted below. Actual

processing conditions will depend on machine size,

mold design, material residence time, shot size, etc.

Additional information on processing may be obtained

by consulting the Bayer publication Makrolon Polycar-bonate — A Processing Guide for Injection Molding

and by contacting a Bayer MaterialSciencetechnical

service representative.

Regrind Information

Where end-use requirements permit, up to 20%

Makrolon resin regrind may be used with virgin

material, provided that the material is kept free of

contamination and is properly dried (see section on

Drying). Any regrind used must be generated from

properly molded parts, sprues, and/or runners. All

regrind used must be clean, uncontaminated, and

thoroughly blended with virgin resin prior to drying

and processing. Under no circumstances should

degraded, discolored, or contaminated material be

used for regrind. Materials of this type should be

properly discarded.

Improperly mixed and/or dried regrind may diminish

the desired properties of Makrolon resin. It is critical

that you test finished parts produced with any amount

of regrind to ensure that your end-use performance

requirements are fully met. Regulatory or testing

organizations (e.g., UL) may have specific requirements

limiting the allowable amount of regrind. Because

third party regrind generally does not have a traceable

heat history or offer any assurance that proper

temperatures, conditions, and/or materials were used

in processing, extreme caution must be exercised in

buying and using regrind from third parties.

The use of regrind material should be avoided entirely

in those applications where resin properties equivalent

to virgin material are required, including but not

limited to color quality, impact strength, resin purity,

and/or load-bearing performance.

Regulatory Compliance Information

Some of the end uses of the products described in this

bulletin must comply with applicable regulations, such

as FDA, NSF, USDA, and CPSC. If you have any

questions on the regulatory status of these products,

contact your Bayer MaterialSciencerepresentative or

Bayer’s Regulatory Affairs Manager in Pittsburgh, Pa.

General Characteristics of Polycarbonate

Hydrolytic Stability. Parts molded from polycarbonate

absorb only 0.15 to 0.19% water at room temperature

and 50% relative humidity. Dimensional stability and

mechanical properties remain virtually unaffected. Even

with immersion in water, dimensional changes measure

only about 0.5%. Although frequent, intermittent contact

with hot water does not harm polycarbonate, continuous

exposure to humidity or water at high temperatures

(>140°F/60°C) is not recommended due to hydrolytic

degradation, which reduces impact strength and

tensile properties.

Gas Permeability. Steam permeability, measured on

100-µm thick film, is 15 g/m

2

.

24 h (0.97 g/100 in

2

.

24 h).

Significant permeability also exists for other gases, such

as hydrogen, carbon dioxide, sulfur dioxide, helium,

ethylene oxide, and oxygen.

Chemical Resistance. Polycarbonate is resistant to

mineral acids (even in high concentrations), a large

number of organic acids, many oxidizing and reducing

agents, neutral and acidic saline solutions, some

greases and oils, saturated aliphatic and cycloaliphatic

hydrocarbons, and most alcohols. It is important

to note that polycarbonate is degraded by alkaline

solutions, ammonia gas and its solutions, and amines.

Polycarbonate dissolves in a number of organic

solvents, such as halogenated hydrocarbons and some

aromatic hydrocarbons. Other organic compounds

cause polycarbonate to swell or stress-crack, e.g.,

acetone and methyl ethyl ketone. Since chemical

resistance to various media is dependent on variables,

such as concentration, time, temperature, part design,

and residual stresses, the above information should

serve only as a guideline. It is imperative that production

parts be evaluated under actual application conditions

prior to commercial use.

Health and Safety Information

Appropriate literature has been assembled which

provides information concerning the health and safety

precautions that must be observed when handling the

Makrolon resins described in this bulletin. Before

working with these products, you must read and

become familiar with the available information on their

hazards, proper use, and handling. This cannot be

overemphasized. Information is available in several

forms, e.g., material safety data sheets and product

labels. Consult your BayerMaterialSciencerepresentative

or contact Bayer’s Product Safety and Regulatory

Affairs Department in Pittsburgh, Pa.

ASTM Makrolon®2405/2407

b

/2458

Typical Properties* Test Method Resins

for Natural Resin (Other) U.S. Conventional SI Metric

eneral

pecific Gravity D 792 1.20

ensity D 792 0.043 lb/in3 1.20 g/cm

3

pecific Volume D 792 23.1 in3/lb 0.83 cm

3

/g

Mold Shrinkage D 955 0.005–0.007 in/in 0.005–0.007 mm/mm

Water Absorption, Immersion at 73°F (23°C): D 570

24 Hours 0.12%

Equilibrium 0.30%

Melt Flow Ratea

at 300°C/1.2-kg Load D 1238 20 g/10 min

ptical

ransmittance at 0.125-in (3.2-mm) Thickness D 1003 88%

aze at 0.125-in (3.2-mm) Thickness D 1003 <0.8%

efractive Index D 542 1.586

Mechanical

ensile Stress at Yield D 638 9,400 lb/in

2

65 MPa

ensile Stress at Break D 638 8,700 lb/in

2

60 MPa

ensile Elongation at Yield D 638 6%

ensile Elongation at Break D 638 115%

ensile Modulus (1 mm/min) D 638 350,000 lb/in

2

2.4 GPa

lexural Stress at 5% Strain D 790 12,000 lb/in

2

83 MPa

lexural Modulus D 790 340,000 lb/in

2

2.4 GPa

ompressive Stress at Yield D 695 11,000 lb/in2

76 MPa

mpact Strength, Notched Izod: D 256

73°F (23°C)

0.125-in (3.2-mm) Thickness 14 ft•lb/in 750 J/m

ensile Impact Strength, “S” Specimen: D 1822

0.125-in (3.2-mm) Thickness 250 ft•lb/in

2 525 kJ/m

2

ockwell Hardness: D 785

M Scale 75

R Scale 120

hermal

eflection Temperature, Unannealed: D 648

0.250-in (6.4-mm) Thickness

264-psi (1.82-MPa) Load 259°F 126°C

66-psi (0.46-MPa) Load 273°F 134°C

oefficient of Linear Thermal Expansion D 696 3.34 E-05 in/in/°F 6.0 E-05 mm/mm/°C

hermal Conductivity C 177 1.39 Btu•in/(h

•ft

2

•°F) 0.20 W/(m•K)

pecific Heat D 2766 0.28 Btu/(lb•°F) 1,172 J/(kg•K)

elative Temperature Index: (UL746B)

0.059-in (1.5-mm) Thickness

Electrical 125°C

Mechanical with Impact 115°C

Mechanical without Impact 125°C

icat Softening Temperature, 50N; 50K/h D 1525 291°F 144°C

lammability**

xygen Index D 2863 28%

L94 Flame Class: (UL94)

0.75-mm (0.030-in) Thickness V-2 Rating

1.5-mm (0.059-in) Thickness V-2 Rating

2.7-mm (0.106-in) Thickness HB Rating

3.0-mm (0.118-in) Thickness HB Rating

Weatherability

V Light Exposure and Hot Water Immersion Tests (UL746C)

Makrolon 2407 and 2458 resins f1 rating

lectrical

olume Resistivity (Tinfoil Electrodes) D 257 1.0 E+16 ohm•cm

urface Resistivity D 257 1.0 E+16 ohm

ielectric Strength (Short Time Under Oil D 149

at 1-mm [0.04-in] and 73°F [23°C]) 810 V/mil 32 kV/mm

ielectric Constant (Tinfoil Electrodes): 60 Hz D 150 3.0

1 MHz 2.9

issipation Factor (Tinfoil Electrodes): 60 Hz D 150 0.0008

1 MHz 0.01

rc Resistance: Stainless Steel Electrodes D 495 11 s

Tungsten Electrodes 120 s

These items are provided as general information only. They are approximate values and are not part of the product specifications. Type and

quantity of pigments or additives used to obtain opaque colors and special effects can affect material properties.

Flammability results are based on small-scale laboratory tests for purposes of relative comparison and are not intended to reflect the hazards

presented by this or any other material under actual fire conditions.

For information on using melt flow as a quality control procedure, see the Bayer publication Makrolon Polycarbonate — A Processing Guide

or Injection Molding.

Makrolon 2407 resin is UV-Stabilized.

Note: The information contained in this bulletin is current as of November 2002. Please contact Bayer MaterialScience

to determine whether this publication has been revised.

Sản phẩm khác cùng loại

- Hiện chưa có sản phẩm

HỖ TRỢ TRỰC TUYẾN

Hotline: 0904 022 133

Hotline: 0904 022 133 Phòng KD hạt nhựa: 024.3776 7722/33, ext: 102; 103

Phòng KD hạt nhựa: 024.3776 7722/33, ext: 102; 103 Email: sales@alphachem.com.vn

Email: sales@alphachem.com.vn Phòng KD hóa chất: 024.3776 7722/33, ext: 104; 105

Phòng KD hóa chất: 024.3776 7722/33, ext: 104; 105 Email: sales@alphachem.com.vn

Email: sales@alphachem.com.vn Fax: +8424.37767744

Fax: +8424.37767744 Email:

Email:- Facebook Hóa Chất Alpha

-

binh.alpha

binh.alpha

TÌM KIẾM NÂNG CAO

NHẬN TIN SẢN PHẨM MỚI

HOẠT ĐỘNG

- Thông báo nghỉ Tết Nguyên Đán Canh Tý 2019

- Tuyển Trưởng phòng kinh doanh hạt nhựa kỹ thuật - Business Manager

- Tuyển dụng Trưởng phòng kinh doanh/Nhân viên kinh doanh hóa chất, hạt nhựa

- Tuyển Nhân viên kinh doanh hóa chất

- Tuyển nhân viên kinh doanh hóa chất, hạt nhựa

- Thay đổi tên công ty và địa chỉ văn phòng

- Đoàn Hiệp hội Giấy Việt Nam tham dự FAPPI 31 tại Indonesia

- Công ty cổ phần giấy việt trì 50 năm xây dựng và phát triển

- Công ty CP giấy Việt Trì tự hào với truyền thống 50 năm xây dựng và phát triển

- Triển lãm China International Water Chem Exhibition 2013 lần thứ 9

LIÊN KẾT WEBSITE

- Công ty Cổ phần XNK Bắc Giang (Nhà máy Giấy Xương Giang)

- Công ty Cổ phần DEVYT (Nhà máy Giấy BBP)

- Công ty Cổ phần Giấy An Hòa

- Công ty Cổ phần Giấy Bao bì Đồng Tiến

- Công ty Giấy Tissue Sông Đuống

- Công ty TNHH Xưởng Giấy Chánh Dương

- Tập đoàn Giấy Tân Mai

- Công ty TNHH Giấy Trường Xuân

- Công ty TNHH Giấy Kraft Vina

- Công ty Giấy Hải Phòng

- Tổng công ty Giấy Việt Nam (Nhà máy Giấy Bãi Bằng)

- Công ty Cổ phần Giấy Việt Trì

- Trang Web Danh bạ các công ty hóa chất

- Công ty Cổ phần Giấy Sài Gòn

- Công ty cổ phần Sản xuất và thương mại P.P

- Công ty cổ phần Giấy Vạn Điểm

- Thời báo kinh tế - Diễn đàn Doanh Nghiệp Việt Nam

- Giấy – Wikipedia tiếng Việt

- Hiệp hội giấy và bột giấy Việt Nam (VPPA)

- Tin tuc 24h | tin nhanh bong da | the thao | thoi trang, giai tri vn

- Báo Dân trí – Thông tin mọi lúc, mọi nơi tới mọi người, mọi nhà

- Tin nhanh VnExpress - Đọc báo, tin tức online 24h

LƯỢT TRUY CẬP

- Đang xem

- Hôm nay 193

- Tổng lượt truy cập 4,088,486

THÔNG TIN TIỆN ÍCH

BÀI VIẾT MỚI NHẤT

- Tuyển dụng Trưởng phòng kinh doanh/Nhân viên kinh doanh Hóa chất, Hạt nhựa

- PAC và ứng dụng trong xử lý nước

- Cần tuyển nhân viên kinh doanh hóa chất, nhựa

- Tuyển 01 lái xe văn phòng

- Xử lý nước thải sản xuất giấy

- Lịch sử sản xuất giấy

- Các chất phụ gia trong ngành giấy

- List of Customers

- Nhựa thông trong kỹ thuật gia keo bề mặt cho giấy

- Nguyên nhân và cơ chế của hiện tượng bóc sợi

- Các bệnh giấy thường gặp và cách khắc phục

- Keo chống thấm AKD

- Chất độn cho giấy

- Nhuộm màu cho Giấy

- Khách hàng

- 6-8/6/2013: Triển lãm Quốc tế về ngành Giấy và Bột giấy Việt Nam

- Chất trợ bảo lưu Percol 182

- Tuyển 01 nhân viên kinh doanh hóa chất

Bình luận

Chưa có bình luận nào!

Phản hồi

Bình luận từ Facebook