- TRANG CHỦ

- GIỚI THIỆU

- SẢN PHẨM

- Nguyên liệu ngành nhựa

- Hóa chất ngành Giấy

- Trợ bảo lưu và thoát nước

- Chất tăng bền ướt

- Chất phủ lô

- Hóa chất giặt chăn lưới

- Chất diệt khuẩn

- Tăng trắng huỳnh quang

- Lơ tím, xanh

- Trợ chống thấm bề mặt

- Phẩm màu cho giấy bao bì

- Phẩm màu cho giấy bìa màu

- Hóa chất cho giấy tráng phủ

- Chất phá bọt

- Chất tăng bền khô

- Hóa chất xử lý nước thải

- Chất phân tán Tissue

- Chất khử mực

- Hóa chất ngành sơn

- Nguyên liệu xi măng

- Hóa chất công nghiệp

- Hóa chất ngành dệt nhuộm

- TIN TỨC

- KỸ THUẬT

- KHÁCH HÀNG

- TUYỂN DỤNG

- LIÊN HỆ

DANH MỤC SẢN PHẨM

TÀI LIỆU KỸ THUẬT

- tdsp640j.pdf

- propertyanalysiswt45ancalpha.pdf

- tdspalmac1600alpha.pdf

- tdspalmac1500alpha.pdf

- stearicacid1838alpha.pdf

- coaofstearicacidr401860alpha.pdf

- deepwhiteabpxpowderalpha.pdf

- kymenẹ57htangbenuotvn.pdf

- prosofttq28881.pdf

- tdskymene705.pdf

- kymenẹ57htds.pdf

- hyt80tdsenalpha.pdf

- snowhite80tdsvietnam.pdf

- pmmacm207.pdf

- pc110uiso.pdf

- opticalbrighteningagent2plc.docx

- opticalbrighteningagent4plcvn.pdf

- melaminetdsalpha.pdf

- coazncl2alpha.jpg

- tdszncl2alpha.pdf

- pc1220ueng.pdf

- pc1100u.pdf

- pc1070ueng.pdf

- absag15átds.pdf

- ppk8009tdsen.pdf

- absterlurangp35.pdf

- absterlurangp22.pdf

- bakelit161jcoaalpha.pdf

- bakelit151jcoaalpha.pdf

- bakelit141jcoaalpha.pdf

- bakelit141coaalpha.pdf

- makrolonet3117isoen.pdf

- makrolonet3113isoen.pdf

- makrolonal2647isoen.pdf

- makrolon2807isoen.pdf

- makrolon2407isoen.pdf

- alphavncompanyprofile.pdf

- Bài viết

- Optical Brightening Agent in paper making

Ngày đăng: 03/07/2013, 11:21 am

Lượt xem: 809

Lượt xem: 809

WET END: Addition Points FWA & Colorants

•The number of sulphonic groups on the FWA determines the solubility of the molecules. Highest solubility has hexasulpho, lowest disulpho.

•The lower the solubility, the higher the fiber affinity.

•Only di- and tetrasulpho should be used in Wet End (normally).

•Higher affinity allows later addition point.

•Late addition of FWA means faster response times and less interference with other chemical additives. Always consider the dosage points for other chemicals (especially cationic additives).

•Higher affinity gives higher first pass retention of FWA and consequently faster grade changes.

•The addition level of shading colorants is relatively low: 25-200 g/ton of dry paper.

•Direct Dyes (mainly anionic) have enough affinity to be added without fixation etc.

•Basic Dyes (cationic) should only be used for wood containing (or recycled) pulp. Due to high affinity for lignin, mottling can occur with fiber mixtures (e.g. 20% CTMP/80% Kraft).

•Pigment Colorants have low natural affinity and retention increases with total retention.

•Late addition point of colorant makes the shade control faster.

•Dilution requires purified water and hygienic conditions. Failures in dilution- and dosage systems are common reasons for broke.

WET END: Factors influencing the FWA performance

•Pulp brightness

• Furnish

• Water hardness

• pH

•Cationic additives

• Filler

• Consistency & Contact time

•Shading Colorant

SIZE/FILM PRESS:Factors influencing the FWA performance

SIZE/FILM PRESS:Factors influencing the FWA performance

•Base Paper: Sizing, pH, Fillers, Liquor pick-up

• Size Press Liquor: Anionic- & Cationic starches

• Carriers: CMC, PVA

Base Paper:

•Sizing: Naturally, the level of Sizing influences the pick-up of the base paper. Furthermore, highly cationic-, neutral sizes and rosin size (with alum) has a negative effect on the size press FWA (as on the wet end FWA). Tetrasulpho’s are more sensitive than hexasulpho.

•pH: A base paper pH below 5.5 has a significantly negative effect on tetrasulpho FWA’s and greening occurs early. Hexasulpho is much less affected. There is also a buffered tetrasulpho formulations available; TINOPAL ESP Liquid, that are tailored for acidic conditions and works well also with highly cationic sizing systems. .

•Liquor pick-up: The higher the amount of FWA carried onto the paper by the starch solution, the higher the whitening effect. The build-up goes to a certain point after which greening starts.

•Fillers: The brightness of the filler has a large impact on the whiteness also in size press. Base paper filled with CaCO3 (esp. PCC) has an increasing effect while e.g. Clay has a decreasing effect on whiteness

COATING: Factors influencing the FWA performance

COATING: Factors influencing the FWA performance

•Pigments

•Binders

•Co-binders

•Solid content

•Base paper

•FWA distribution in single coat/double coat

•Shading Colorants

Pigments:

Mainly, combinations of china clay (increases gloss) and CaCO3 (increases whiteness) are used as pigments in coating colors. For high-quality coated papers and boards, special products such as satin white, titanium dioxide, aluminium hydroxide, modified clays, and synthetic pigments are also used.

The pigments have very little effect on whitening performance. They primarily affect the base white. The higher the base white, the lower the amount of FWA required to achieve a given effect and the higher the maximum whitening effect.

Binders:

The binders added to coating colors are essentially dispersions based on

– styrene-butadiene lattices

– styrene-acrylate

– vinyl acetate

All binders are anionic and have no affinity for FWA’s and, like pigments, have only a negligible influence on the whitening. The natural color of the latex will however have an influence on the whiteness.

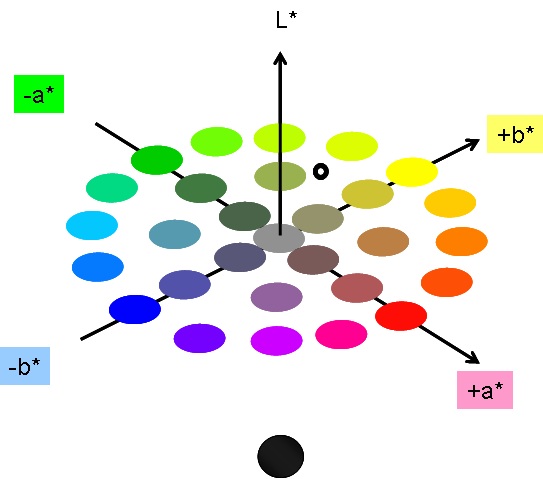

Together with SB-latex, it has been observed that tetrasulpho FWA sometimes gives a higher b*-value (yellower => lower whiteness) than disulpho FWA at the same brightness level.

Co-binders:

FWA’s in coatings require a so called booster, also known as a carrier.

Typical boosters are:

Co-binders: PVA, CMC, starch, etc. which are added to the coating color to adjust the rheology. They also influence the water retention of the coating color.

Polyethylene glycols (PEG): Normally added (up to 40%) in some FWA formulations (mainly tetra- and hexasulpho type), but can also be added directly to the coating color. PEG-boosted FWA’s are especially useful in coating colors with low (<0,5%) or no co-binders or when the highest whiteness levels are required.

However, independently of the amount of co-binder, the PEG-booster always increases the maximal achievable whiteness and shifts the saturation point (the point where greening occurs) to much higher FWA-concentrations.

Bài viết khác

HỖ TRỢ TRỰC TUYẾN

Hotline: 0904 022 133

Hotline: 0904 022 133 Phòng KD hạt nhựa: 024.3776 7722/33, ext: 102; 103

Phòng KD hạt nhựa: 024.3776 7722/33, ext: 102; 103 Email: sales@alphachem.com.vn

Email: sales@alphachem.com.vn Phòng KD hóa chất: 024.3776 7722/33, ext: 104; 105

Phòng KD hóa chất: 024.3776 7722/33, ext: 104; 105 Email: sales@alphachem.com.vn

Email: sales@alphachem.com.vn Fax: +8424.37767744

Fax: +8424.37767744 Email:

Email:- Facebook Hóa Chất Alpha

-

binh.alpha

binh.alpha

TÌM KIẾM NÂNG CAO

NHẬN TIN SẢN PHẨM MỚI

HOẠT ĐỘNG

- Thông báo nghỉ Tết Nguyên Đán Canh Tý 2019

- Tuyển Trưởng phòng kinh doanh hạt nhựa kỹ thuật - Business Manager

- Tuyển dụng Trưởng phòng kinh doanh/Nhân viên kinh doanh hóa chất, hạt nhựa

- Tuyển Nhân viên kinh doanh hóa chất

- Tuyển nhân viên kinh doanh hóa chất, hạt nhựa

- Thay đổi tên công ty và địa chỉ văn phòng

- Đoàn Hiệp hội Giấy Việt Nam tham dự FAPPI 31 tại Indonesia

- Công ty cổ phần giấy việt trì 50 năm xây dựng và phát triển

- Công ty CP giấy Việt Trì tự hào với truyền thống 50 năm xây dựng và phát triển

- Triển lãm China International Water Chem Exhibition 2013 lần thứ 9

LIÊN KẾT WEBSITE

- Công ty Cổ phần XNK Bắc Giang (Nhà máy Giấy Xương Giang)

- Công ty Cổ phần DEVYT (Nhà máy Giấy BBP)

- Công ty Cổ phần Giấy An Hòa

- Công ty Cổ phần Giấy Bao bì Đồng Tiến

- Công ty Giấy Tissue Sông Đuống

- Công ty TNHH Xưởng Giấy Chánh Dương

- Tập đoàn Giấy Tân Mai

- Công ty TNHH Giấy Trường Xuân

- Công ty TNHH Giấy Kraft Vina

- Công ty Giấy Hải Phòng

- Tổng công ty Giấy Việt Nam (Nhà máy Giấy Bãi Bằng)

- Công ty Cổ phần Giấy Việt Trì

- Trang Web Danh bạ các công ty hóa chất

- Công ty Cổ phần Giấy Sài Gòn

- Công ty cổ phần Sản xuất và thương mại P.P

- Công ty cổ phần Giấy Vạn Điểm

- Thời báo kinh tế - Diễn đàn Doanh Nghiệp Việt Nam

- Giấy – Wikipedia tiếng Việt

- Hiệp hội giấy và bột giấy Việt Nam (VPPA)

- Tin tuc 24h | tin nhanh bong da | the thao | thoi trang, giai tri vn

- Báo Dân trí – Thông tin mọi lúc, mọi nơi tới mọi người, mọi nhà

- Tin nhanh VnExpress - Đọc báo, tin tức online 24h

LƯỢT TRUY CẬP

- Đang xem

- Hôm nay 7

- Tổng lượt truy cập 3,972,003

THÔNG TIN TIỆN ÍCH

BÀI VIẾT MỚI NHẤT

- Tuyển dụng Trưởng phòng kinh doanh/Nhân viên kinh doanh Hóa chất, Hạt nhựa

- PAC và ứng dụng trong xử lý nước

- Cần tuyển nhân viên kinh doanh hóa chất, nhựa

- Tuyển 01 lái xe văn phòng

- Xử lý nước thải sản xuất giấy

- Lịch sử sản xuất giấy

- Các chất phụ gia trong ngành giấy

- List of Customers

- Nhựa thông trong kỹ thuật gia keo bề mặt cho giấy

- Nguyên nhân và cơ chế của hiện tượng bóc sợi

- Các bệnh giấy thường gặp và cách khắc phục

- Keo chống thấm AKD

- Chất độn cho giấy

- Nhuộm màu cho Giấy

- Khách hàng

- 6-8/6/2013: Triển lãm Quốc tế về ngành Giấy và Bột giấy Việt Nam

- Chất trợ bảo lưu Percol 182

- Tuyển 01 nhân viên kinh doanh hóa chất

Bình luận

Chưa có bình luận nào!

Phản hồi

Bình luận từ Facebook